-

Coverings

I’ve been plodding away on the boxing in the spare room. I filled and sanded the screw holes, used expandy foam, filler and caulke around the edges, and painted the whole thing with primer. The final step was a couple of coats of white wood paint. I located a pot and painted the wood. Then, looking up at the rest of the ceiling I realised that also needed some caulke and another coat, so I moved on to that. It’s an annoying job but I was pleased to get it done.

Until that is I looked back down at the paint I’d been using and realised it was gloss… Chris claims it’s not particularly obvious but there are definitely shiny patches. It’s low on the priority list but at some point I’ll go over it again with satin paint.

In the utility I covered the rough lime plaster with a coat of pure lime to create a better finish. Where I’d done lime coats last week I used filler to cover the cracks and the smooth over the edge of the doorway.

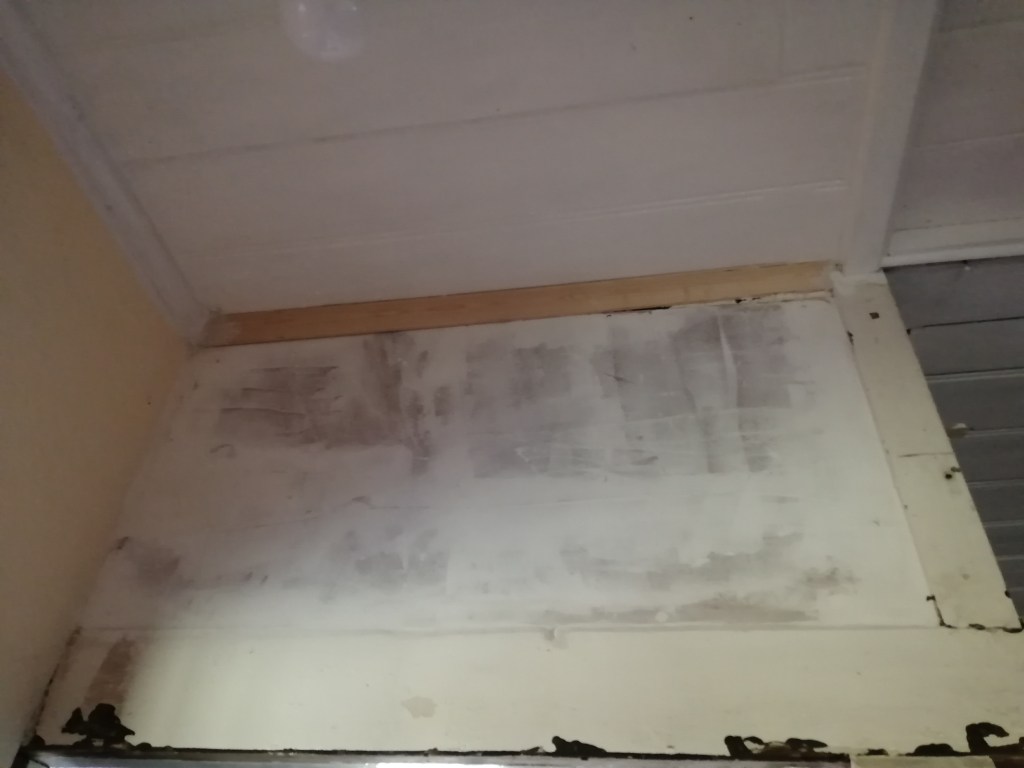

I got round to attaching the last bit of insulated board over the lintle in the study. It just needs filling and painting next.

But the big job was getting on with the shed. Chris had spent an evening attaching the boards to the roof, and another moving gravel to backfill around the base. This meant we could move straight onto cladding the outside. We cut the waney edge spruce to size and overlapped it from the base to the roof. On the roof we cut and attached bitumen roof sheets.

The shed is pretty weatherproof now, with only a few final bits of cladding needed, as well as the windows to install. Soon we should be able to move in some of our tools, and clear out the house a little. Chris is on the look out for old kitchen cabinets to start building a work bench.

-

Shedding

I can’t say that I’m particularly excited about building the garden shed. This is largely because there are undone jobs I look at every day inside the house I’d rather be getting on with. But Chris has been dreaming of a shed ever since we moved in, and says I can’t replace the stairs till the tools are out of the house – hence a shed.

We borrowed Chris’s brother’s cement mixer and spent last weekend laying the concrete slabs for the base. As I can’t lift the slabs on my own, Chris laid the slabs while I wheelbarrowed sand from the drive to the cement mixer, and then wheelbarrowed cement to shed base, in a continuous loop for hours. For something that looks like such a small job it took a full day, and was pretty exhausting.

With the base done and dried, we started on building the shed itself this weekend.

Chris has spent several evenings pondering on the design. He was keen to maximise the size so he could use it for tinkering on projects in the future. We also had an old door, two of our old windows, and some second-hand shelves that had to be worked into the design. My only inputs were a request for a green roof, an entrance for swallows, and an inbuilt bug hotel.

I spent my time cutting the wood to size while Chris hammered them together into frames. Once the frames were together we lifted them up and bolted them together. We then screwed the frame to the floor with a vapour membrane beneath it.

Next Chris cut the joists for the roof and we used a gravelboard from the shed base to begin constructing the roof.

A few more joists to put in and next weekend the larch boards should arrive the clad the outside. It might not be one of my priority jobs, but at least it’s moving on quickly.

-

Background features

With weekends pretty busy I’ve been trying to get a few little jobs done in the evenings where possible. But I really wanted to get on with some bigger jobs so decided to book off a few days to help move things forward.

I’d been itching to panel the back of the breakfast bar for ages, but Chris said I couldn’t do it till he finished the extractor fan. The breakfast bar looks much better, though Chris says you can’t notice the change much as we currently use this space to store items for the recycling center and resale, but one day it’ll be empty and ready for some bar stools.

We decided to use architrave to cover the gap at the back of the breakfast bar. I treated the wood with the same stain as the worktop and chopped it up. Unfortunately, there a lot of odd angles along the back of the breakfast bar, and Chris had to give me a hand working out how to calculate the angles.

I finished off the downstairs toilet cupboard doors with hinges, door knobs and closing mechanisms.

Chris finished up the last of the tiles in the utility, and you can’t tell they went in after the other tiles.

To finish off the edging in the utility Chris added an entrance strip between the two tiles.

I boxed in the ventilation pipe in the spare room. It was a horrible job, with cutting the shape of the wood to match the ceiling taking an age. I then attached the final bit of coving. Next it will all need filling, sanding and painting.

I’ve been avoiding a number of small plastering jobs because they’re a pain, but I got down my list and couldn’t avoid them anymore. I plastered the wall in the downstairs toilet with lime mortar, and filled the utility doorway with the remaining mix. I then smoothed out some previous lime mortar surrounding the doorway and above the doorway on the landing with lime plaster.

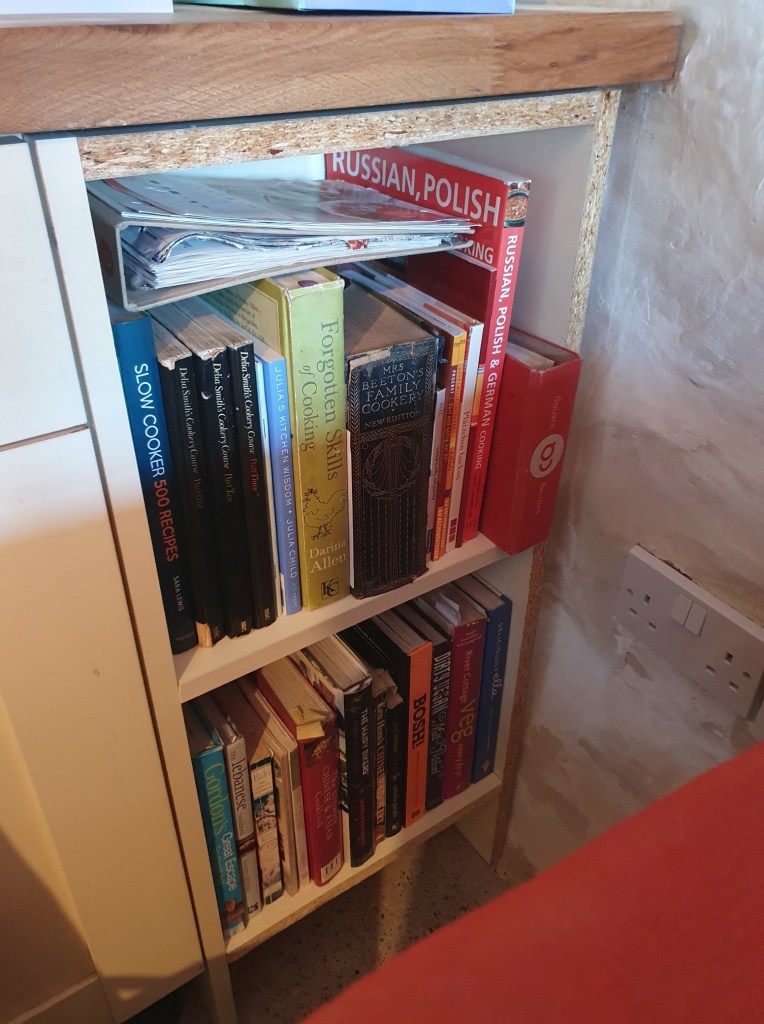

In a gap under the worktop Chris used the spare cupboard shelves to create a small bookshelf for our kitchen books. He’ll then use some iron on edging to cover the exposed wood. This tiny bookshelf means another moving box is finally emptied.

Chris’s brother has lent us a cement mixer, and Chris plans to start laying the slabs for the shed. A big order of wood has also gone in for the structure – meaning the kitchen will once again be piled high with building supplies, but still it’ll be exciting for the shed to start going up. We just need a little sunny weather to help it along.

-

Filling some gaps

We only had one day free this weekend for DIY, so I made an effort to get through a few small jobs in the evenings.

I gave the lounge beams a final coat of paint, before washing the brushes, putting everything away, and then remembering the one solitary beam in the utility that still needed painting.

When we first moved in we left Idris alone for one of his first evenings without us and he decided he’d burrow his way out through the door. Luckily he now feels more comfortable in the house on his own, so it seemed time to undo the damage. I used a chisel to smooth out the worst of the roughness, then sanded it down before adding a coat of stain to the bare wood. The whole door then got another coat, and the frame a couple of layers of the brown paint.

Where the edge of the concrete floor meets the door, there’s a ugly gap, which needed a piece of trim to cover it. I cut it to size, primed and paint it, and stuck it down. It’s a very small change but it’s surprising how much its changed the room.

I having previously started the skirting in the kitchen I had to stop as the new doors weren’t in. I restarted, but remembered how complicated the tiny bit of remaining skirting was going to be – as the lack of space beside the door means they’ll have to be trimmed down. I managed one piece and moved on to something simpler.

I continued with the boiler doors, building them in the same vein as the previous door. The only added complication was that the frame needed a bit of additional support, which meant using expandy foam to stick pieces of wood to the wall to screw the boards to. Still all done now, just in need of hinges to finish the job.

Chris’s big job for the weekend was finally connecting up the extractor fan, which was a fiddly task, involving cutting holes through the cupboard and getting all the electrics connected up. Chris was triumphant to finally put the fan on and see it drawing in the steam. The only negative is that he got his electric wires mixed up and now you press the ‘-‘ to turn the extractor up and ‘+’ to turn it down…

We’d spent out Saturday morning cleaning the layers of dust ready for visitors, only to have new layers laid down after our day of DIY on Sunday. A never ending cycle of dust and dusting. At least it’s slightly less dust with each passing cycle.

-

Fiddly and annoying

It’s been a long time since I last posted – that’s largely because it’s been a long time since we’ve been able to do a decent bit of DIY. Between our holiday to Norway, friends weddings and a few other commitments, we’ve barely had time to pick up a hammer. Although it’s nice to do other things, it’s also frustrating when nothing progresses and we’re stuck looking at the same uncompleted jobs day after day. But finally we had a weekend free to get back to work.

We’re at the stage in the renovation where it seems all the remaining jobs are ones we’ve been putting off because they are so annoying to do, and relatively unsatisfying. The downstairs toilet ceiling is an awkward mass of pipes, making it fiddly to get the plasterboard up and in place. I got to work on a day when Chris was busy and was pretty pleased I managed to hold the board up with one hand while screwing it in place with the other. There was lots of swearing involved.

Chris’s big achievement, on a day where a power outage meant he couldn’t work for a few hours, was finally putting shelves in place in our tiny bedroom cupboard. I then primed and painted them, so we can finally use this space.

Continuing on the theme of cupboards I returned to the frame I’d built in the downstairs toilet and added a back and side panel before installing shelves. After spending ages on the internet getting quotes for custom doors for £250, we decided to make our own, so I spent some time cutting out boards to build the first door, with another two to go for the boiler cupboard.

In the utility both new doors needed the edges filling and sanding. Chris also spent some time adding a door handle and door jam to the interior door.

In the lounge I’d been putting off repainting the beams, but Chris told me we couldn’t get new flooring until we’d done it, so I bought the paint and chipped away a few at a time in my evenings. A thankless task but it does mean I can stop staring at all the white paint drips.

In the garden the neighbours have been getting a little nosy. Chris decimated our box hedge in the hope it grows back a little happier next year.

He also borrowed a compactor off a neighbour to compact down the shed base so we can lay the concrete slabs. Just need it to stop raining long enough for us to get on with it.

Also in the garden, the sinkhole has reopened. We thought it was still active as a few of the trees are leaning over into it, but now a new hole has opened up. We’ll have to buy some gravel this time to fill it up, which seems a waste. Just hope it eventually becomes full.

Chris’s big success has been getting the second external vent in for the ventilation. This means the whole system is now in place, it just needs wiring up. I don’t have any photos of the process, as Chris doesn’t take any, and I was busy cupboard building, but it involved lots of crawling around in the attic and climbing onto the roof.

Still, now the ventilation is largely finished I can finally clean out the study, which has largely been used as a ventilation pipe storage room for the last few months. Getting one more room looking like a room is certainly be a little more satisfying than some of the other jobs I have on my list. Still any job ticked off is still a job ticked off, however small and annoying it is.

-

DIY to the Max

Unfortunately for my cousin Max, his name makes a good pun – bad luck. However, it has felt like a good week for DIY, with his arrival not only giving us always welcome extra pairs of hands, but giving us a boost too. Max arrived on the Friday night and stayed till the following Friday. So he wasn’t on his own too much, myself and Chris both took off two days to work on the house, so it really felt like we got a good amount done.

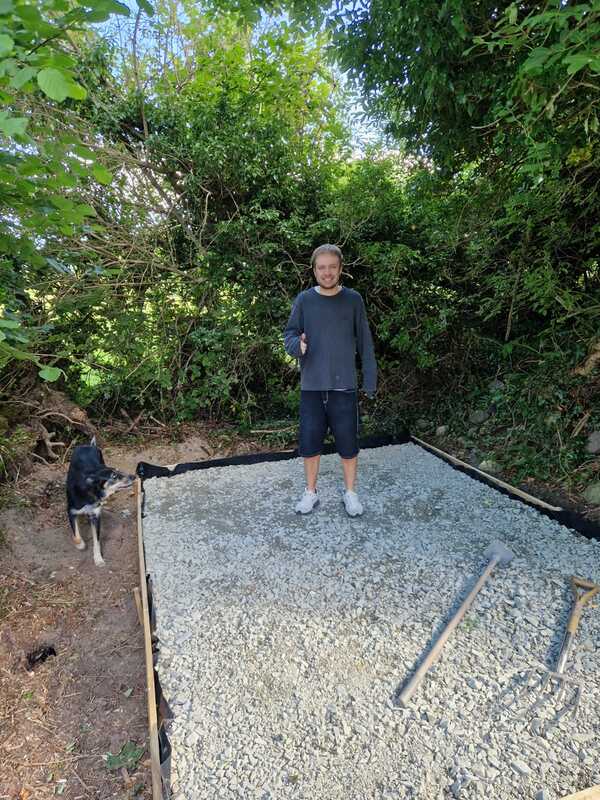

We did give Max the option to rest after his long journey, but he decided to dive right in, starting by clearing the corner of the garden where the shed will go.

Later in the week he returned to the job, leveling the ground, securing gravelboards and wheelbarrowing in load after load of gravel.

On the weekend myself and Chris focused on the van, with Chris working his way through the electrics, while I cut the awkward pieces for the roof. It was exciting to have the lights and the fan finally working.

I then focused on building the kitchen units and attaching boards to the sides of the kitchen and the bed.

Chris added the worktop and began connecting up the electrics across the van.

Chris and Max removed the old lintle over the back door, propping up the wall with acro props, and inserting the concrete lintle. Once in, Max was left to rebuild the wall above and mortar everything in place. The end result is seemless with the old wall.

With the new lintle in and set, Max and Chris set about removing the old door. The frame of the back door was too rotten to save, so the whole thing had to be cut out. We’d bought a plain PVC door for this space, as it won’t be on display, as this will be our muddy boot room. Together, Max and Chris got the new door in and secured without too many issues.

Another door we’d been putting off was the doorway between the kitchen and the utility. The wonky walls, with one just plasterboard and the other solid stone, meant we’d known it was going to be a pain to do.

With a pipe running down one side of the opening, we realised the doorway would be too small if we put it on the inside of the pipe. The solution was the attach the frame above the pipe, which was fiddly. Max lent a hand with the tricky process, and eventually everything was secured in place. Chris then added the doorframe and cut the door to size.

One particularly exciting job, was the shaping of the last bit of worktop. Chris had been putting it off because it was going to be so awkward and time consuming, but in the meantime we’d had to shuffle passed the worktop taking up half the doorway to the utility. Now it’s cut to follow the cupboards it opens up the space completely.

Another annoying job that we’d been avoiding was building the boxing round the boiler in the downstairs toilet. Awkward because of all the piping on the ceiling, and the fact that the beams were at different heights, and the floor has a slight slope towards the boiler. To provide stability to the boxing I started with the cupboard next to the boiler, setting shelves at approximately the right heights for our cleaning products. Still work to do but getting there.

Between his other jobs we asked Max to replace the insulated plasterboard on the windowsills in the spare room. It had collapsed when we’d had to climb all over it when installing the windows.

I finally got a curtain pole and set of curtains up too.

My final job of the week was to start making the covers for the campervan bed. I haven’t sewn in years since I had to relearn the process. They might not be the fanciest cushions, but fine for our first few trips.

Chris and Max raised up the scaffolding up once again to install the external parts of our ventilation system.

Phew – it’s been an intense week, with everything that’s been going on, but fantastic to get round to some of those more awkward and tricky jobs. Hopefully Max has enjoyed getting stuck in to the DIY, we’ve certainly appreciated the help. Hopefully the little boost will keep us going till our trip to Norway in a few weeks. Still plenty to do in the meantime – four more cushion covers to sew for a start.

-

Van 5: Making the bed

The amount of time I’ve spent on coving four windows would be hard to believed. They’re finally done; filled, sanded, and caulked. Although they are a tiny detail in much bigger rooms, it’s amazing how much more finished they make the rooms look. So they may be bodge jobs, because the angles were impossible to calculate, but I’m still pretty happy with them.

Out in the van it’s all similarly mathematical, as we moved on to building the bed frame. Chris has found a design online, which was fairly simple to follow. Still it took a long time cutting every piece and putting them together.

We started with the back bench, which needed two sets of hands to keep everything in the right place while joining them together.

The sides were easier for me to get on with on my own, so Chris could concentrate on the electrics, which is the biggest headache of doing up a van, and something I don’t understand in the least.

With the benches built, we cut down the mattress we’d bought into the right sizes, so they can be benches or a bed, when needed. Now these are all cut up my next evening job will be sewing the covers.

We then started to get the ceiling on, Chris laying the wire for the lighting first.

Outside the van, the garden is coming along well. It still looks like chaos, but slowly some order is forming. As part of this I’ve started shaping the rambling roses into a coherent form, pulling in tendrils to create a sphere. It’s a bit of an experiment, but hopefully it will mean I can form them into a kind of rose topiary. The other garden roses are starting to put on a show, and I look forward to the day when the garden is full of the scent of roses.

-

Van 4: Making good

Now the van is insulated it’s time to make it look less like a van and more like somewhere you can live. Our first job was cutting and attaching thin sheets of plywood to the wall. We’re a little undecided whether to paint them or just varnish, so for now we’ve been as regular as possible with the screws to keep it looking tidy if we go with varnish. There are some some gaps between the boards, which will need filling. The one patch of wall we’ve left is the bathroom, which will need something more waterproof to line it.

While Chris installed the electric hook up in the van side, I filled any holes or dips on the floor, before sanding it flat.

With the floor a little less bumpy we unrolled the lino and cut it shape.

We then got on with building the storage. We’d decided to have a raised floor under the bed/benches for extra storage. To build this, Chris had found a design online and adjusted it to our needs. With thick plywood on top to act as a suspended floor we’ll next build benches on top, with a table that can convert into a bed. Sounds complicated.

Inside the house I’ve spent a few evenings faffing around with the coving over the windows. It’s not an easy job with wonky walls and a slanting ceiling, but finally all the coving is attached, and will just need filling, and sanding and caulking…. Nearly there.

The dog has decided he doesn’t like leaving us unsupervised in the camper, so the compromise is he sleeps on the front seat while we work behind. It doesn’t look as comfortable as being asleep on the sofa, but at least it means he’s getting used to being in the van.

-

Scuppered by gravity

I’ve had quite a long break from drystone walling, but after a particularly irritating teams meeting I got out in the garden to build some more, my own bit of meditation. It’s a bit of a unstable wall at the moment as I need to backfill in a number of the places, having built the wall straight when the earth bank isn’t.

But come the weekend it was back to the campervan. Unfortunately, our plans were a bit undone this weekend when Chris woke up on Saturday morning feeling terrible. He therefore got the day off to lay on the sofa and I did what I could on my own.

Firstly, I had to clear the kitchen to lay out the flooring from the van, on top of the insulation to allow me to cut it out. Chris did have to get up briefly to help me move some of the heavier furniture out of the way to make space.

The template worked really well and I only had to shave a small amount off one corner to get it to slot in.

Prior to the insulation going down a couple of cables needed to be laid to be connected up later.

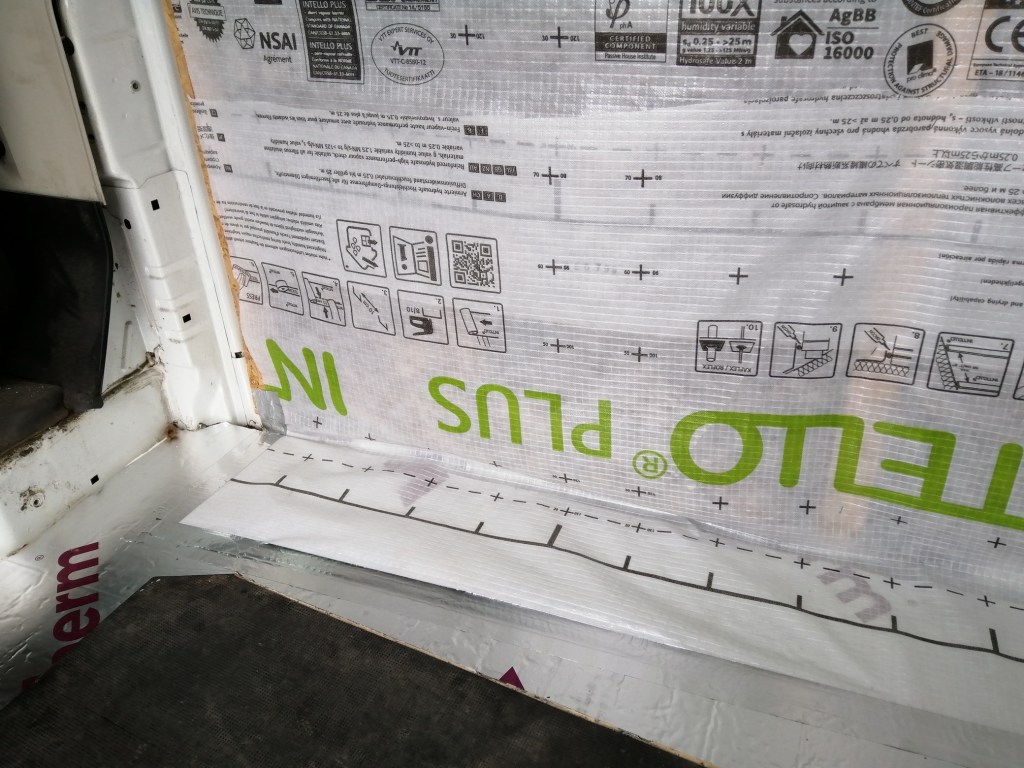

I then cut and attached additional vapour membrane where it was missing. The vapour membrane was then taped to the floor and membrane added over the wheel arches.

The solid flooring now put back down, and screwed into place through the old screw holes, I had to pack insulation around the wheel arches and tape to tops to the wall to seal. An awkward present to wrap.

I felt pretty pleased with my progress on my own, particularly as I had a late start after fetching supplies for Chris. So when Chris said he would be well enough on Sunday to lend a hand I thought we’d fly along the rest of the jobs…

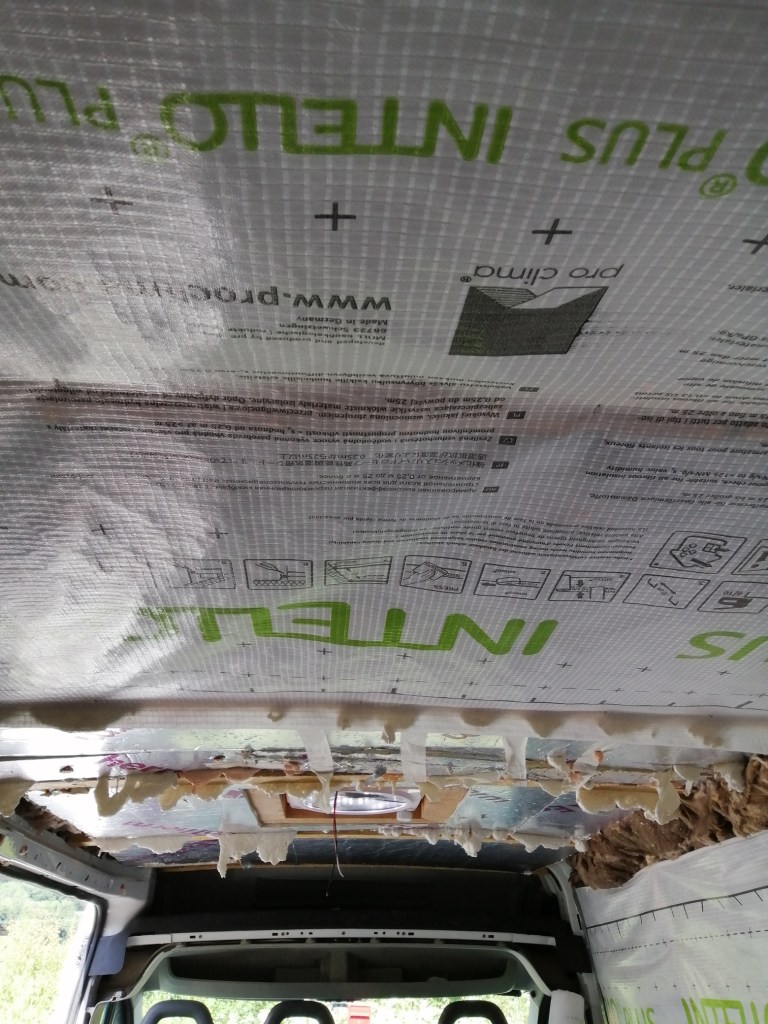

Sadly, Sunday was a bit of a disappointment. We’d hoped to get onto building the structure and the electrics, but the ceiling just sapped all time out of the day with two simple jobs.

Firstly, Chris wanted to get the ventilation fan in place, needing to cut out a hole in the metal and then secure it in place. With one thing and another the job took most of the day as it refused to fit, and it turned out we didn’t have the right wood.

The job I spent my time on, after adding more insulation to a few awkward places in the walls, was trying to get the insulation to stay on the ceiling. Firstly, I needed to drill holes for a special bolt system for the batons that the ceiling would attach to, but despite the instructions recommended a 7mm drillbit the bolts just slid back out. Not a good sign.

When that was finally resolved we attempted to stick the remaining insulation up with expanding foam, as the specialist spikes we’d brought didn’t work. Unfortunately, the foam didn’t harden quickly enough so in the end we had to screw in batons to keep the insulation in place while it dried.

Finally, we got to fill the remaining gaps with expandy foam and attach the vapour membrane to the ceiling. It felt like a very unsatisfactory day, with it feeling like we’d barely moved the needle. But hopefully now the ceiling is at least fixed in place, things might be a little easier with most of our jobs no longer fighting gravity.

I had a particularly cheeky visitor one day, a lamb escaped from the neighbouring field. I wouldn’t have minded his presence, except he insisted on eating my prettiest flowers, so in the end I had to herd him back home. He can come back when he’s learnt to appreciate my planting scheme.

-

Van Post 2

Stage two of the van transformation was to insulate it. As someone that feels the cold this is a particularly important step for me. We’ve gone for slightly unusual insulation, as it’s actually the same stuff we insulated our house with. Chris found someone selling all the materials the contractors had left behind at a very cheap price.

The one problem with using materials not designed for the job was that we needed to prise the unneeded plasterboard off the insulation, a surprising difficult job.

Before attaching the insulation we first cut up and applied a sound deadening material to the various panels. This should reduce noise when driving the van.

Sticking the insulation on the ceiling was a pain. Even though Chris had brought special attachments to make it easier, the glue kept failing and the boards were constantly falling down.

The batons were cut to shape and attached to the side of the van.

We wedged soft insulation between them, as well as stuffing it into every nook and cranny. In general, it’s not recommended to use this kind of insulation in vans, as moisture can condense between the van interior and the insulation, however we’re using the same vapor membrane as in the house so moisture won’t get in to the insulation.

Next, we took up the floor of the van. We’ll reuse the existing boards, but need to lay insulation underneath.

Chris spent a bit of time sanding back and priming any small areas of rust.

As usual we didn’t get as much done as we were hoping, but still most of the insulation is in place, on to the electrics next week!

As always I’ve been trying to tick off a few jobs inside the house during the evenings to make up for concentrating on the van on the weekends. I finally finished filling, sanding, caulking and painting the new wood covering the window lintels, a fiddly and thankless job.

In the bathroom I finally got round to grouting the splashback.

Above our bedroom door I filled, and sanded the plasterboard, before attaching the final piece of coving and filling and caulking around it.

And, after filling and sanding the places where the wood had rotted away at the bottom of the doorway, the front door got another coat of yellow, and the ironwork a coat of black.

The garden is full of flowers at the moment, particularly the irises. I’d love to get more of the garden done with summer in full swing, but the van takes precedent… Lots to do and always little time.

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.