-

With a little Help from our Friends

Having originally thought we could keep the existing open fireplace, Chris eventually realised it was too rusted to save, and found a replacement.

We started by chipping out the old fire, which went surprisingly easily.

Next we needed to sweep the chimney, but this was easier said than done. The chimney was unfortunately not entirely straight, with a kink part way up. Try as we might the chimney brush didn’t want to get past this bend. Eventually we decided to thread the poles up without the brush. Chris then climbed up to the roof and attached the brush. We were then able to pull it down. We repeated this a couple of times.

Coming back down from the roof Chris bumped into our neighbours, Joe and Suzie, themselves in the midst of a renovation. Talking through what we needed to do next – installing the new flexible metal flue – Joe was quick to volunteer a hand, having been through the pain of flue installation in his own house.

With that Chris and Joe set to work, with Suzie acting as a runner for tools and supplies. It turned out the reason we couldn’t get the brush up the chimney was due to a huge bundle of sticks, left behind by jackdaw nests. After a struggle to get this out, which included Chris getting into the chimney like a Victorian child, the chimney was finally ready for the flue.

The dogs (Idris and Chris’s aunt’s dog Kiwi – a lodger for the weekend) were surprisingly unbothered by the dust and noise, and merrily spread sooty footprints around the house.

With so many helping hands I felt at a bit of a loose end. I have to admit, at eight months pregnant, I had been finding crouching in front of the fireplace fairly exhausting. Additionally, the ensuing battle with the flue that Chris and Joe had would definitely have been beyond my physical strength, so we were very glad of the help. With nothing to do, I did some tidying of our cleaning cupboard, a new set of sorting boxes having recently arrived, made cups of tea, and popped to screwfix for a few additional pieces.

While I ‘kept busy’, Joe and Chris spent their time going up and down the roof, huffing and puffing, while they tried to thread the flue past the awkward kink in the chimney. Between them, finally the flue was in place, after some three hours of hardwork.

The next day, our helpers gone, it was back to me and Chris to move the fireplace forward. Though the flue was in place, we needed to move it up to get the solid metal flue attached and in place, to connect to the stove.

Chris climbed back onto the roof to try and pull the flue back up, while I tried to maneuver and push from the bottom. A couple of hours later the flue had moved about a foot, nowhere near enough. Both of us pretty tired, I suggested we needed to try something different.

My first suggestion was to break into the chimney where the bend was, to help force the flue past the bend (as suggested by the Internet if the flue gets stuck). Chris really didn’t fancy this idea, both for the extra mess and the work.

Second idea was to cut the flue shorter from the bottom, to give space to attach the solid metal flue. Chris pointed out he wouldn’t be able to reach high enough in the chimney to attach the flue. ‘If only I’d bought the shorter flue’ he said – I asked why we couldn’t just cut down the one we had. Finally, something made sense. Chris cut down the solid metal flue, and cut back the flexible flue inside the chimney, having just enough reach within the chimney to attach it all together, and bring the stove in to the space below. After hours of struggle, suddenly everything came together very quickly. Sometimes cheating is just the best way. Finally, Chris returned to the roof to cut back the flue at the top and attach the chimney cowl.

The hardwork was done, all that remains is to fill in around the stove and replaster.

Once the new plan had taken hold, Chris really didn’t need me (apart from listening out for him falling off the roof), so I set to work sanding beneath the bathroom radiator. We couldn’t reach under the radiator with the electric sander, so we’d planned to remove the radiator at some point in order to finish the job. However, Chris had realised with the bedroom floor that hand sanding was a viable option.

I’d been hoping to leave this job to Chris as crouching isn’t the most comfortable at the moment, but all the other jobs on my to do list involved painting, which didn’t seem a great idea with a house covered in soot. The finished job might not be quite as good as removing the radiator to sand, but it was a lot less hassle.

With Chris all done, all that remained was a deep clean of the house, though I’m sure we’ll be wiping away soot for months to come.

-

Trip hazard

I’ve been meaning to paint the utility for ages. Being one of the rooms I plastered, Chris wasn’t happy with the smoothness of the finish, so post first-coat I filled in the worst of the bumps, with the plan to cover it up in the second coat. There was also the plasterboard around the new doorway that needed its first coat.

However, having opened the old pot of paint I realised there wasn’t enough to finish off the whole room. I just managed half the room before I had to give up and order a new tin.

The following weekend, with my new tin, I set to work on a second coat to the plasterboard and final coat for the rest. Before I started however, I had to attach and caulke a bit of skirting that has been previously missed. There were also a few rough spots of the wall in need of filler.

The wall next to the machines we decided to leave white, to stop the room feeling too narrow.

Chris’s big job was getting in the newel post at the top of the stairs. It’s not really needed, however we couldn’t cut off all the top of the stairs without making them unstable, and what needed to stay was a bit of a trip hazard, so the newel post would engulf the top of the stairs, and give a hand support for people heading down.

It was a tricky job as the base of the post had to be cut to engulf the stairs, and then a new piece of wood pasted in to make the outside of the post look neat. The whole thing was then attached to the wall.

The post was partly important to get in as we’re soon getting carpet installed on the landing, and it needed to be in place before that happened.

Chris’s other job was to install some bedside tables. As our bed had pulled out drawers, all the bedside tables we have stopped them from opening. Chris therefore cut off two legs and attached the table to the wall, allowing the draws to open.

Another nice job was putting up some pictures throughout the house. We have two of our dog Idris, one by my mum and the other by Chris’s cousin, in pride of place on the landing.

Chris had spent a long time finding a suitable second-hand woodburning stove for the lounge, needing to fit the hole that would be left by the old one. Luckily he found a fairly new one that had recently been taken out by the company that installed it, as the owners had had an extension and needed a bigger one installed. It’ll be a big dusty job, so definitely worth doing before the baby arrives.

-

Second coat

Sometimes things take an age but at the end you don’t seem to have much to show for it – that’s very much true of the second coat of paint.

The second coat on the study/baby room wasn’t too bad except shifting around the various bits of bobs currently housed in there. Having filled and sanded under the windows, there were a few patches needing covering up, but mostly it looked the same post paint. Still very much worth doing before the carpet gets fitted.

Because the green paint covered and blended so well we decided not to repaint the whole room but just paint where we filled around the windows, which was much quicker.

A bigger job was lugging around furniture so the room made a little more sense. Having moved into the pink room, any furniture we didn’t want has been dumped in the spare. In time we may get rid of a few items, as they aren’t really needed.

Though the pictures don’t really show the change the landing was a noticeable refresh. As we’re carpeting this area soon it made sense to repaint now, including a coat of yellow and repainting the stair wall post filling. There’s still the other side of the stairs to paint, but the wall is so high I’m not sure how we’ll reach the top.

The plaster surrounding the stone wall had never been painted, so that was nice to do. However, being a small area I convinced myself it wouldn’t take long. Because of its rough uneven surface the whole thing had to be done with a brush, making take an age.

With a few walls painted we actually went as far as to start hanging a few pictures. I didn’t necessarily agree with where Chris wanted them, but as I end up making most of the decorating decisions in the house, I figured it was probably his turn to make a choice.

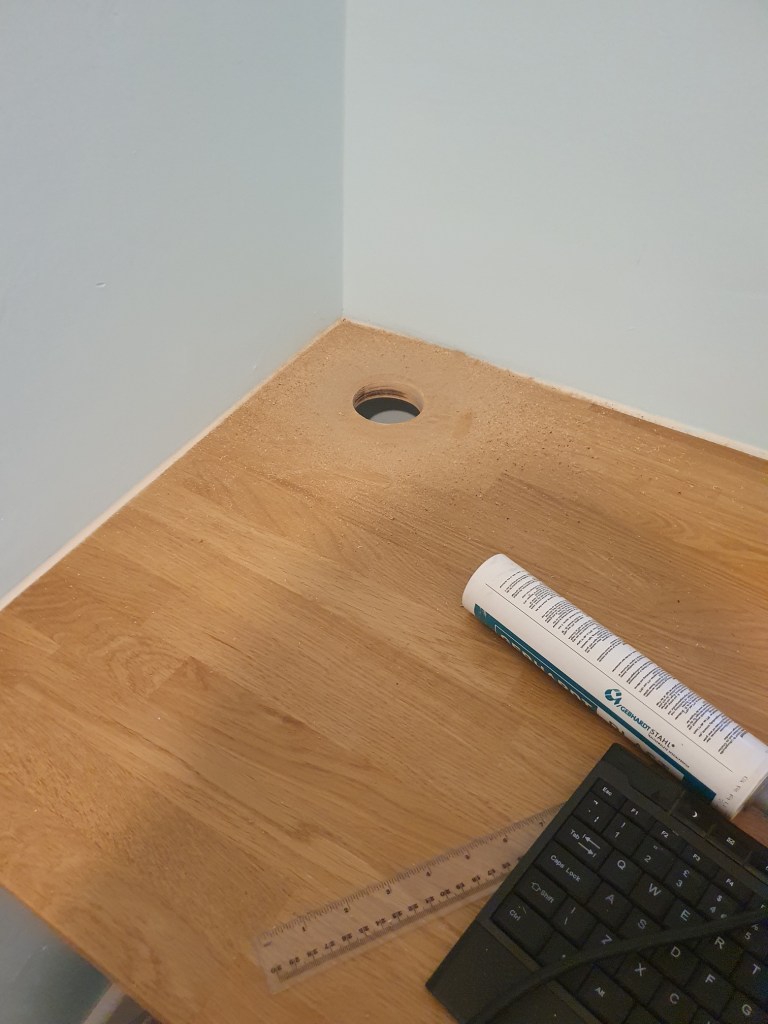

While I was busy painting, Chris got on with a few jobs that had been bothering him, including cutting holes through the desk for wires, and finally fitting an awkward bit of floorboard on the landing.

Well it doesn’t feel like much, but it’s taken enough time. Chris also picked up a second-hand built-in stove for the lounge. This will be a big messy job to get the old one out and new one in, so good to do before the baby arrives. Apparently at 8 months pregnant and I’m not allowed to help, so we might have to call in a favour for the lifting into place.

-

One down…

With a hectic Christmas over, I think both of us just wanted to collapse on a sofa and not get up until it was time to get back to work. But with very few weekends left till the baby arrives, it seemed wise to push through and get on with some DIY.

The floor in the spare bedroom, which will be ours once the baby arrives, had been sanded but never treated. In order to get on with the job, we had to clear the room, including taking apart the bed.

Room clear, Chris gave the floor a sand to refresh it before cleaning and treating. In the other rooms we’ve used a basic clear varnish, but we had some of the treatment left from the cork floor so decided to use that instead. Annoyingly it looks much nicer than the basic varnish, so we wish we’d used this on the other rooms now. It took two coats with four hours drying between to get the floor ship-shape.

While Chris focused on the floor I continued with windowsills. First they needed attaching, now I had a new countersink (naturally we found the old countersink not long after). I screwed the windowsills down into the wood below, helping to hold them in place and flatten out wavy corners.

Screwholes and any gaps then needed to be filled and sanded. We decided the two spruce windowsills could do with darkening to match the rest. We had some of the oak stain left from the wooden beams so I gave them two coats of that, which did the job.

All windowsills attached, fill and sanded, the final job was two coats of the same treatment we were using for the wooden floor. Overall I’m really pleased with the end result. Fitting windowsills for our large window recesses.

One of the reasons I wanted to get the windowsills in was because it’s the last job needed in many of our rooms before they can have their final coat of paint.

With the varnish dried, I caulked around the edges, and filled the exposed board beneath the large windowsill in the spare bedroom. At the same time Chris filled some rough patches on the walls. Everything sanded, I started on the final coat of paint.

I made my way round the room applying the second coat to the walls, and another coat to the skirting and arcitrave. Stretching up and kneeling down is quite tiring work when 31 weeks pregnant, but finally the bedroom is done.

Now we can start to move our things in, and hang up pictures. With the windowsills finished in the study and other bedroom too, these can now also have final coats of paint. It’s getting tight to the deadline, but it’s feeling a little more achievable with one room ticked off.

-

Layers

It’s always the little jobs that seem to take an age. After previously filling and sanding the skirting in the lounge and part of the kitchen, I thought I’d do the quick job of painting it. However, the cheap and cheerful wood paint we’d brought was thin as water, and four coats later the small section of skirting had taken me half a day.

In the lounge, the much better quality cream heritage paint covered in two coats, and the TV unit is finally finished.

Upstairs I wanted to attach the windowsill in the spare bedroom but Chris reminded me he wanted the thicker insulated plasterboard replacing with the thinner fibre cement board. The reason was because the thicker board caused the windowsill to sit quite high on the windowframe. I felt a little bad replacing it given this was the third time, installed once by the contractors, only for my knee to go through it when we were installing the window, and then replaced by Max on his DIY week. Still at least all the boards were left overs from the previous work.

Frustratingly, having installed the new board it turned out the countersink bit was no where to be found, so I couldn’t install the windowsill after all.

So, with no luck installing windowsills, I moved on to cutting out the wood for the last one. Awkwardly the remaining wood was only just wider enough so I couldn’t afford to lose much in the cutting.

Having cut out the pieces I left them to dry for a few days before planing the edges and joining the pieces, and leaving the whole thing to set in the shed.

It wasn’t too tricky to cut the windowsill to shape for once, with just a couple of trims needed. I then used some wood filler on the gap for this new windowsill and the one I’d previously made for the study.

With that, and a bit of dry weather, I took both of the windowsills outside for a sand. The spruce was much rougher than the elm, and so harder to sand, but it came out well after working through a couple of grades of sandpaper.

Both done and back in their places, they just need attaching, screw holes filling and sanding, and treating… once we’ve bought a new countersink bit.

After umming and ahhing and ordering so many different tile samples the tile company rang me up, we finally settled on a pink for the downstairs toilet windowsill. I’ve marked them ready to cut, we just need to dig out the tile cutter.

While I’ve been ticking off the odd job here and there Chris has been preoccupied with a mixture of attending Christmas parties, working and being ill. However, he did manage to finally set up and install our weather station. He’d ordered it so we could monitor our wind speeds, with the plan to install a small wind turbine at some point to add to our green energy.

Phew – it’s felt a busy build up to Christmas but we’re finally here. A few days with family to do nothing but eat and slob around, and then a brief bit of DIY chaos to build up to the New Year – what else could you want?

Merry Christmas!

-

Inside – outside

We spent half a day sorting through several moving boxes currently living in our study, trying to remember why we have so much stuff. By the end we managed to relocate many of the items to elsewhere in the house, or offer them up to charity. What remains is a box of pictures and another of photo albums, both of which won’t find homes till after the final coat of paint. While not the most exciting job, this gets us one step closer to carpeting the study, which will be the baby’s room, so worth a slow start to DIY this weekend.

Released from box sorting I decided to try and finish off the corner cabinet. First the side panels needed attaching. To do this I had to screw in some batons to attach the panels to, a little tricky in the small space but doable.

Before they can be attached they needed painting, so I coated them in primer before doing the same with the top shelf of the TV unit and the new shelf and brackets in the bookcase.

The rest of the unit got a quick sand, to tidy up some filler, and a coat of cream paint. The whole thing now needs a second coat, as do the pieces coated in primer, but this can’t happen till everything has dried.

I moved on to filling the screw holes and joins on the skirting.

Having some leftover filler I tried to smooth out some lumpy patches on the ceiling. Clearly a poor repair, before our time, we’d ignored it as none urgent, but I’ve been finding it more and more irritating, so filler it is.

While everything dried out downstairs I cut a cardboard template for the final windowsill upstairs, ready to cut out the final pieces of wood another day.

While I was labouring away inside, Chris had opted to brave the rain outside the house, working first on his car before moving on to give the hedge its winter cut. Cutting back the laid hedge will encourage it to thicken up, which will make it better for wildlife in the long-term. Cutting every other year once established can also be beneficial to leave berries in place through the winter.

He also spent some time tidying the shed. A leaking chainsaw had covered several shelves in oil, and cleaning it up was not a fun job, but a necessary one.

Finally, he spent some time reattaching a downspout at the front of the house, which had fallen off in a previous storm. By attaching an elbow to it we can direct the water away from the house and into the flowerbeds, better for the house and the garden.

Though not big jobs this weekend it’s always good to feel we are moving forward, particularly at such a busy time of year. After all, only three months till the baby is due, and time will be even less available for DIY.

-

Still Windowsills…

Time keeps ticking away, and the baby is getting bigger and bigger. At 25 weeks into the pregnancy we still have plenty we want to get done before the due date. So despite not having much time, with busy weekends and dark, uninviting evenings, we still tried to get a few jobs done, to move forwards bit by bit.

Having glued the planks for the study windowsills, I cut them to size. I needed Chris’s help to lift the bigger windowsill in and out of the alcove to try the fit.

The smaller windowsill wasn’t as tricky, and I managed to trim it down without too much back and forth. All trimmed, I sanded it down using 80 and then 120 grit sandpaper. It needs a little filling and a final sand, before being attached.

Having previously filled the large windowsill in the spare room, I sanded this one down as well.

The smaller windowsill had previously been sanded, but needed another go over to sand back the filler I’d used to fill gaps surrounding the biscuits.

The final windowsill to sand will be a bit of a test run, as this is our first windowsill in spruce as opposed to elm. It’s a much rougher wood so it might need a harsher sand.

After that there’s only one more wooden windowsill to make, and of course all the windowsills to fill, fix and treat.

On a less exciting piece of house admin – I finally emptied the three large, and mostly collapsed boxes, that had been living in the cupboard in our room. Having purchased some plastic boxes I was able to create two crafts and a games box, while rehousing quite a bit to other locations around the house. We still need to build shelving for the cupboard, but at least, after 2yrs of living in the house, we actually know what’s in our cupboard….

-

Time off?

We’d booked off two blocks of time, a Thursday/Friday on week 1, and Wedsday/Thursday/Friday in week 2. We’d hoped long weekend number 1 would get the kitchen floor finished off, but as week 2 rolled round there was still plenty to do.

First we moved the furniture off the final area in need of treatment. Though we’d stopped polishing at a 1,500 pad on this section, Chris had since decided to continue on to 3,000 in other areas, so this patch needed one more polish with the higher pads, several mops to clean it up, and then painting with sealant.

On top of that everything in the kitchen was covered by a thick layer of dust. Cupboards needed cleaning out, crockery, glasses and pans needed washing, every surface and piece of furniture needed wiping down.

It was after Chris helped to move the furniture he announced he was moving on to another job, as one person could finish this job. Sigh.

It was a long and exhausting day, getting the kitchen back into order, but most things are finally cleaned and back in place. Overall, I think the floor does look better, though it doesn’t feel as satisfying as it could for 5 days of two people’s work. But it’s done at least.

The job Chris moved on to was re-laying the steps up to the house. Our steps were a bit of a hazard, with wobbly, uneven slate, threatening to cause a lawsuit at any moment.

Chris has already replaced the top steps, but doing the bottom ones meant digging down a fair way, rather back breaking work.

Having dug out the steps, Chris used some of our piles of stones to create the step bases.

He then reused the tiles we salvaged from the side of the house prior to laying the patio. To give them a bit of stability he mortared in between.

Next we’ll need to rebuild the lower walls beside the path, which have been undermined, and put in a new handrail. Still, a lot safer and nicer looking already.

Having finished the kitchen floor I moved on to more windowsills. I decided to focus on the two windowsills in the study. I managed to reuse the template from the bedroom, with a small addition needed, for the large windowsill.

We are out of large pieces of elm so I cut down two pieces of the same spruce we used to clad the shed. I cut straight edges on both sides of one piece, and one straight edge on the second piece, leaving a wavy edge.

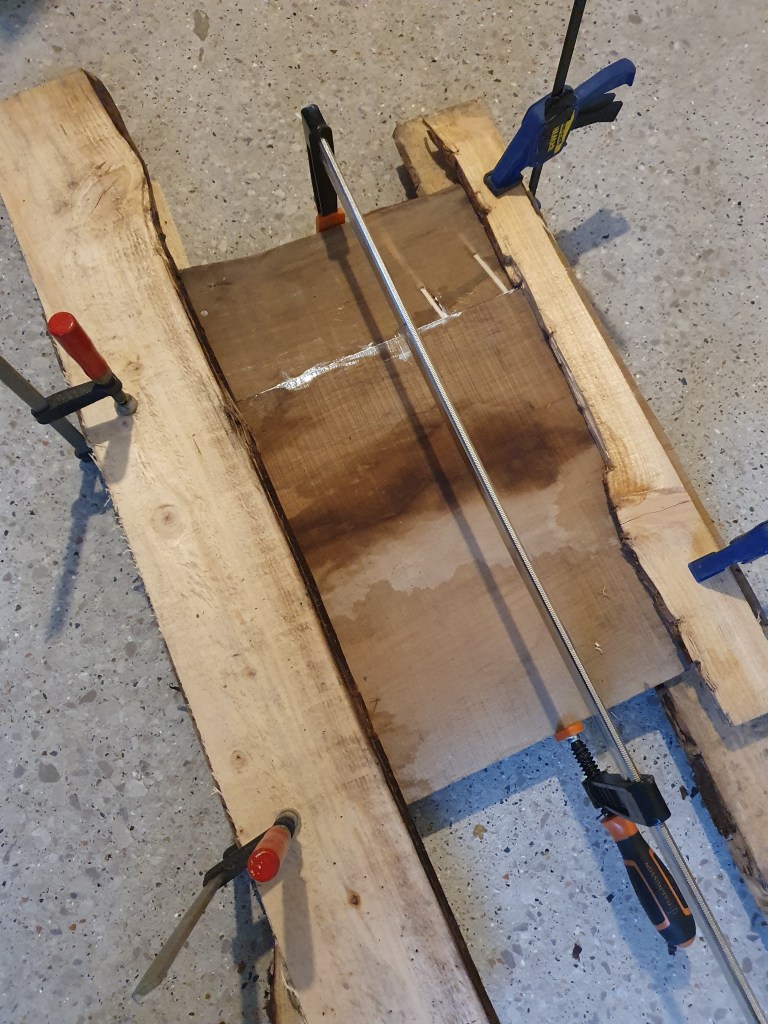

For the smaller windowsill, there was just enough elm to fit the space. Unfortunately, one corner wasn’t quite wide enough, so I had to splice in a third piece of elm. I cut the smaller piece first, clamping both pieces together and cutting the irregular shape in one go, to get a closer match. I then cut the biscuit slits and glued and clamped.

Both sets of boards then needed clamping and planing to get matching edges, before cutting more biscuit slits.

I didn’t have enough clamps to glue and clamp both windowsills so I did the smaller one, and can swap the clamps over once it’s dried. Then both will need to be cut to the template and sanded.

Phew! It’s been a tiring few weeks, but we got through our list of jobs, which is very satisfying. The next few weekends are busy, with few opportunities to progress, so it was nice to take some big steps forward in the last couple of weeks.

-

The Grind

Grouting and regrinding the concrete floor in the kitchen was not a job I wanted to do. Chris had decided on it from the moment we’d finished grinding and polishing it last time, feeling that grouting would fill in some small holes and strengthen the concrete. Having lived through the dusty hell of the first grind I hoped he’d change his mind, however in time we did start to lose little stones from the floor and more holes appeared. The weaknesses are probably because we couldn’t get the concrete compactor to work when we first poured the concrete, meaning it’s not a tough as it should be in places.

With this being a big job, and a horribly disruptive one, we took a couple of days off work to make a long weekend of it.

Our first job was to spread of layer of grout across the concrete. It was a little terrifying thinking that we might just be ruining the floor entirely. Chris got started on the grout, while I emptied our welsh dresser to make it light enough to move, and moved various lighter pieces of furniture into one area of the kitchen so we could work on the rest of the floor. Kitchen rearranged, Chris left me to finish the grouting, while he headed off on other small jobs to keep occupied.

One job I was particularly pleased he decided to do was the skirting in the lounge. I’ve done most of the skirting in the rest of the house and I really hate it as a job. Our walls aren’t straight and the internal insulation makes it hard to find where to attach it to.

As well as fiddly skirting, he attached the lock keep to the study doorframe, and added side panels to the TV unit.

Grouting, as with all the kitchen floor jobs, had to be done a section at a time, as we had to constantly move furniture from one place to another to get to the floor beneath.

Once the grout was dry, hardener had to be rollered on and allowed to dry for 10hours. We managed to grout and harden all the floor on day one, meaning we could start on grinding on day two.

When we ground the floor last time, we hired a larger machine, which you pushed across the floor. This time, Chris brought some pads for our drills, feeling we could get the floor done this way at lower cost. Yes it was feasible, however it took a lot longer, and meant whole days bent over the floor, laboriously grinding away by hand.

To get the floor looking as Chris wanted it, we went through three grinding pads; 50, 100 and 200. We then cycled through a number which tended more towards polishing; 400, 800 and 1500. This mean each section of floor needed 6 passes, with another coat of hardener between the grinding and the polishing pads, plus lugging furniture back and forth. To say it was back breaking work is an understatement.

By the end of day four, one section of floor has been taken all the way to 1500, a second to 400 and the third to 200. We decided to prioritise getting the grinding out of the way, as the polishing pads barely kick up any dust, and we could start to clean up the horrible dusty mess once these were out of the way. I slightly wish I could book another day off to finish the last few stages and get the kitchen back to a clean and tidy order, but unfortunately neither of us have that luxury. It will be polishing and dusting for a couple of evenings instead.

Chris had ordered two sets of pads to allow us both to work on the floor at the same time. Unfortunately, he realised too late he needed an extra part to attach the second set, so for the first day we only had one person grinding at a time, while the other kept busy. My little job was sanding my tiny windowsill for the spare room. Having sanded it down I filled in a few holes with woodfiller, as well as filling the join on the larger windowsill. Once dry I can give the smaller windowsill a final sand, before starting on the bigger job of the larger windowsill.

It’s been such a tiring few days, and it’s frustrating not to have finished the job, still we’re 80% of the way there, and it was always going to be a horrible job to do. It’s been wet autumnal days outside the house, but at least there’s been plenty of rainbows to enjoy after the harshness of the rain.

-

Fitting

Having had an evening out at a local beer festival, Chris didn’t have the energy for DIY, so I decided to crack on with the windowsills on my own. I had the theory down, however, the practice was very rough. I took the previously cut pieces and joined them together with a set of clamps so I could plane along the edge to flatten the join and make them match. Getting it completely flat was a challenge but I got it fairly close.

Next I needed to use the biscuit cutter to cut slots in both pieces of wood. This is where it went wrong. I didn’t realise there was a flap that folded down on top of the wood to keep the cut at the same height all the way along. So instead I ended up with randomised depths of cuts, I then had to match to the second piece. It took me a fair while to rectify, but with a bit of fudging, I managed to join the pieces together.

With biscuits and wood glue applied I now needed to keep the sill flat, using a piece of wood either side with clamps to keep the join from bending and a couple of large clamps to pull them together.

Pieces joined and dried, I used my cardboard template to mark out and cut the edges. I ended up going back and forth to trim several times, not wanting to accidently cut it too small.

Overall it’s not the tidiest job. The gap is a little wider than desirable, and the second smaller piece slants up a little – I think from not using the guide while cutting. Still, for my first attempt I’m happy – and once it’s sanded it’ll look really nice.

Having learn all the ways to go wrong on the first windowsill, the second was significantly easier. First I cut out my missing edge piece from the cracked piece I’d joined with biscuits previously. I then cut off the protruding biscuit edges.

As with the first Windowsill I cut out slits for the biscuits (this time with the guide) glued and clamped.

I’m much happier with this sill, though it was also simpler because it’s smaller. Both just need a lot of sanding and treating now. Only four windowsills to go.

Having rested up, Chris got on with the job of trimming down and hanging the door he made. This was a little more complicated than it should have been as he realised, in order to use some old hinges we had laying around, he needed to remove the architrave we’d already attached. But it’s all up finally, with a handle and everything. Given this will be the babies room in 5 months time, a door is definitely a big plus.

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.