-

A ‘new’ kitchen

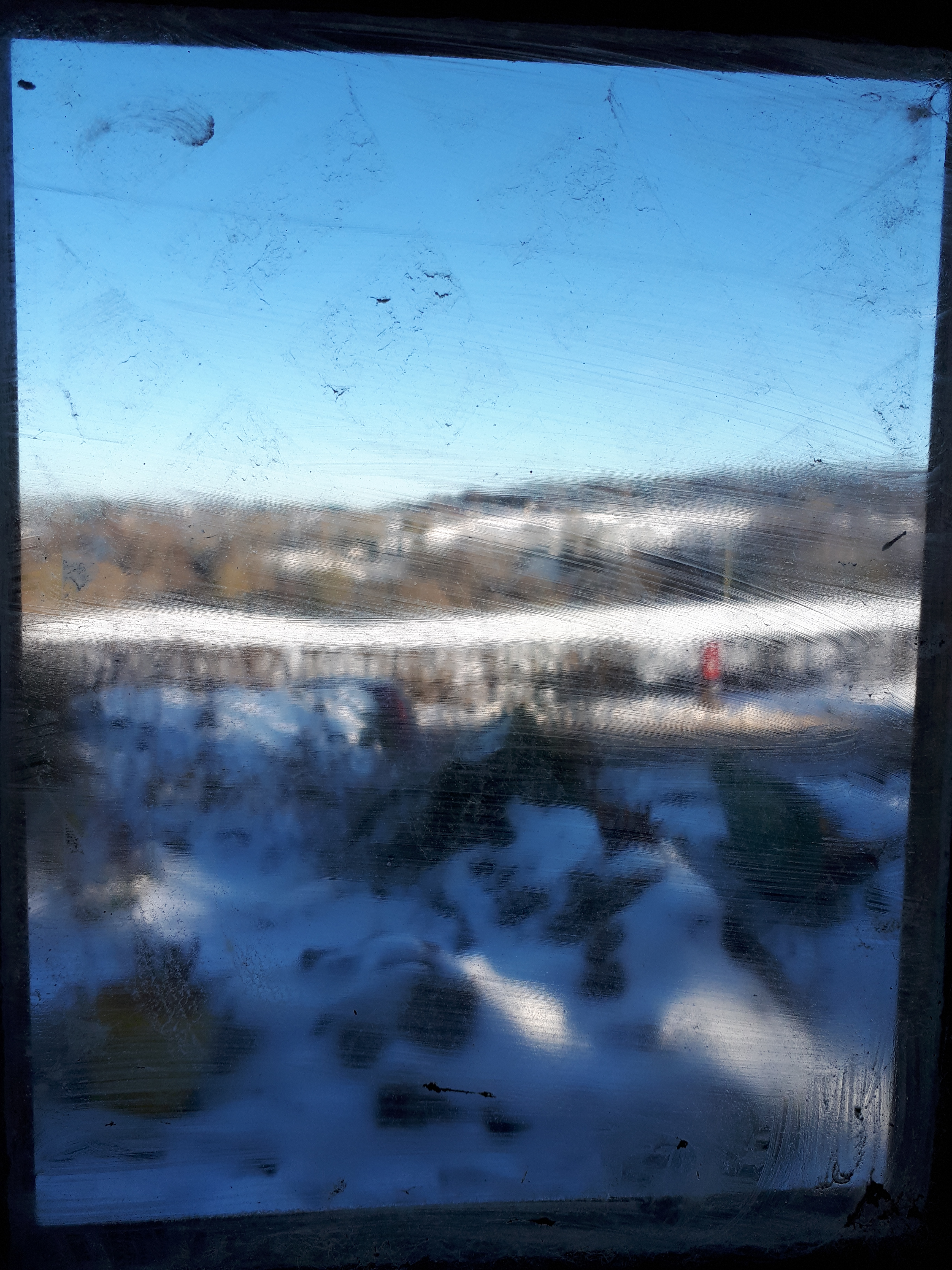

There’s something magical about snow, particularly thick, fresh snow. Yet, while I was excited to see the snow come down heavy on Thursday, we were a little worried when it kept going on the Friday. Having booked a van to go collect our kitchen on Saturday, we didn’t fancy skidding around on the ice. Luckily, while day 1 was traffic chaos, by day 3 the gritters and snow ploughs had gotten things under control.

Having collected the van and headed to the house and we tried to get on with a few small jobs before heading out to collect the kitchen.

Gathering up some of the accumulated rubbish I headed to the recycling center. Sadly, a lot of the rubbish we’re now producing isn’t recyclable, such as expanding foam and insulation board. I always feel like I’ve lost somehow when waste can’t be separated and sent off to a new life. But restoring a house, quickly and to budget, just isn’t possible without creating a good deal of waste.

While I was gone Chris continued with some of the more fiddly bits of lighting electrics he had to sort. Leaving him to it I started to tidy some of the upstairs. With our mortgage inspection coming up in a few weeks we want to get the house a little more orderly, so as to make it look more appealing. Plus it’s nice not to have to step over piles of wood and scattered debris to get everywhere.

With the morning gone we headed out to collect our kitchen. Rather than buy a new kitchen we’d bid for a second-hand one on eBay. The previous owners had removed it from its previous location and it was already in pieces for us to collect. Chris had made sure we’d have enough units to rearrange into the island and floor units we wanted. The kitchen had originally been handmade by a local company, meaning it was a much higher quality than we could have afforded if buying new.

Part of the package were several massive slabs of granite. Although we knew we weren’t going to use them we decided we could take them for resale. As we would never have been able to lift them ourselves, Chris asked his brothers to lend a hand. Rich helped load them into the van at one end and Phil to unload them at the other. Hopefully someone will want them, as it seems such a shame to waste such incredible stone.

Finally, we made our way to the house to unload the kitchen units, made more difficult by the slippery snow on the path. With no floor in the kitchen yet we had to fill the lounge with the units. Hopefully it won’t be long before they can move into their proper place. It’s likely we won’t need all of the units in the end, so we’re planning to sell on whatever doesn’t suit our plans.

Dropping off the van we’d driven around 130 miles in a long day of lugging things to and fro. Exhausting.

Arriving at the house on Sunday we found the winter wonderland gone, with almost all the snow vanished. Our first job was to take down the scaffolding. On Tuesday we’ve booked a concrete delivery, which provides a barrowing service. While we were happy to awkwardly squeeze past the scaffolding we doubted they would be.

Next I installed a strip of foam around the bottom of the wall. This is to allow the concrete to expand and contract as it heats and cools, which can help prevent cracking.

Chris meanwhile installed the manifold for the underfloor heating.

One final piece of the old concrete floor needed to be removed by the door to the garden. Chris had wanted to keep this in place till the last moment to avoid rainwater seeping into the room. Digging out the concrete and attempting to remove the hard clay soil, made me remember how soul destroying the floor excavation had been.

Our last task, to make the floor ready for the concrete delivery, was to lay out boards for the wheelbarrow to travel along. Luckily we have a stack of old doors which we were able to place on wooden blocks so as to protect the pipework underneath. Looking at what needs to be done it feels like Tuesday will be a long day. But hopefully, at the end of it, we’ll finally have a floor.

-

Letting in the light

Our new house has a total of 12 windows, no two alike. While we would have liked to keep the old wooden windows they’re single glazed and in very poor condition. Replacing wood for wood had been our preferred choice, but the cost is prohibitive. Therefore we opted for PVC in the back and wood in the front and side. For our wooden windows we’ll aim to get a similar style to the existing windows, but in the back we decided for the maximum amount of light possible, without unnecessary cross beams.

We started with the two kitchen windows. When we’d first viewed the house these two windows sat in seperate rooms, one in a utility room, and one in a back storage room. Now that they’ll both be facing onto the kitchen worktop, we want them both to be the same size.

First we had to take out the old window and strip the render, in order to remove the bricks below. The work progressed fairly well, with the odd delay when Chris managed to drop first a chisel, then a level and finally the window edging, down the gap between the two faces of the wall. A bit of fishing with a loop of string managed to retrieve them… eventually.

We were keen to have single panes for the kitchen windows as we look straight out onto the back field. Currently this view is overgrown with brambles, but in the future we should get a lovely view of the hill behind the house and grazing sheep, while washing up.

Our first experience of installing windows was on our current house. When Chris suggested attempting installing them ourselves I thought he was being overambitious, and that putting in windows was something only professionals could do. But after a long day of muddling through on our first window we found it really wasn’t that complicated. Now, on our new house, we didn’t even consider paying someone to install them for us.

Having removed the old frames, both of which were so rotten that they practically fell out with a bit of a shove, we readied the new frame by cutting the windowsill to size and attaching it the frame. The window was then put in place, and holes drilled through the frame into the wall to drive in screws into the wall.

Next the window panes were placed in. These are the largest panes in the whole house, and being triple glazed they were heavy to manhandle into place. Once in, the window beading that holds the panes in place, has to be tapped into place around the edge. It’s a challenge to hit the edging hard enough for it to clip in, but not accidentally smash the window, something we learnt when we smashed a window pane in our last house.

With the two kitchen windows finished we moved to the bathroom window upstairs. This window has always been the worst in the house, not closing properly, so we’ve had to tie it with string. It’s had its uses though, as we’ve used it to break into the house on a couple of occasions when we’ve forgotten our keys or locked ourselves out. Guess we’ll have to be more careful from now on.

The window came out fairly easily however, in this room, as with all of the larger upstairs windows, we have the added complication of needing to add a lintle above the window. Removing the window we could even see how the lack of a lintle had caused the roof support to bow in the middle of the window. Unfortunately, this bowing meant the gap was a few millimetres too small for our new window. After a lot of head scratching Chris used a piece of wood to force the center of the lintle to lift enough for us to wedge more stones beneath it, giving us the extra bit of room we needed.

We’d decided to go with one opening panel in the middle of the window, to help air the bathroom when needed. In time we’ll have a bath sat in front of this window to enjoy the view, and I slightly regretted not have one big pane, but losing the ability to open the window wouldn’t have been practical.

In the shower room the small window was much simplier to install, not needing a lintle above, due to its size.

In total we managed to get four out of the six PVC windows installed this weekend. I had hoped perhaps we’d be able to get all six in, but with taking out bricks and installing lintles the time just flew. With moving day seeming ever closer we’ve decided to leave installing the wooden windows till we’ve moved in, as the back windows are in the worst condition. It’s exciting to see the views framed as they’ll be once the house is completed. We’re incredibly lucky with the beautiful views our house affords us, and what better way to do them justice than framing then with picture-perfect windows.

-

Floored

After a few weekends fighting with the floor, Chris had success evening with a rented whacker plate, which compacted the soil down to the right level. Floor finally at the right height he moved in the sand, which was also compacted down using the whacker plate till it was properly flattened.

On Saturday, while I was busy running my monthly volunteer day, Chris continued his good work and got the vapour membrane down before adding insulation.

He also started installing back boxes ready to install our plug sockets.

Joining Chris on Sunday I took over on the insulation board, filling in gaps with pieces of board, before plugging smaller gaps with expanding foam. In order to stop the boards moving too much as we walked across them, we weighted them down with bricks while the foam set. All joins were then taped with insulating tape.

In order to properly join the vapour membrane on the floor with the membrane that had already been installed on the walls, we had to remove the lower plaster boards, so as to tape it down behind the boards.

Upstairs Chris managed to complete a job that had previously annoyed us, installing the insulation board above the window recesses.

With the boards all fixed in place we laid another plastic sheet over the top, which would act as a slip sheet. Marking out where the kitchen cabinets would go we began laying out the underfloor heating pipe everywhere apart from under the future cabinets. It was surprisingly easy to install, unrolling the coil and using plastic clips to fasten it to the floor. It was important to keep the pipe around 20cm apart from the next run, and to end up back where we started, so we curved our way round the room with care.

At the end it looked a pretty smart job, almost like we knew what we were doing. Finally the floor is ready for the concrete. Having initially thought we might mix the concrete ourselves we decided in the end to order a cement lorry. Always nice if someone else can do some of the hard work.

As the shell of the house slowly gets closer to completion Chris has been hunting down some bargains. He managed to win a £400 shower door and tray at an auction for £30, and picked up a toilet someone was getting rid of for free. With the concrete floor so close to completion we’re just getting ready to bid on a used kitchen. He keeps reminding me we have a lot of do still, but it’s feeling more and more like a liveable house with ever step we take. Which is lucky when our own house sale is now in the hands of the solicitors…

-

Undermining

Around a week ago we arrived at the house to find our insulation installers had had a bit of an accident. Opening their van something must have tumbled out, spilling thousands of polystyrene balls onto our drive. As environmentalists the sight of all this litter was horrifying. Unfortunately, we didn’t have a hoover to attempt a clean up. Remembering this weekend to bring a hoover I set to work trying to clean up the mess. Sadly, lots of the balls had already been trodden into the mud, making it really difficult to get everything. Still the hoover did its job and I got the vast majority off our drive. Bring on the day when all polystyrene is banned!

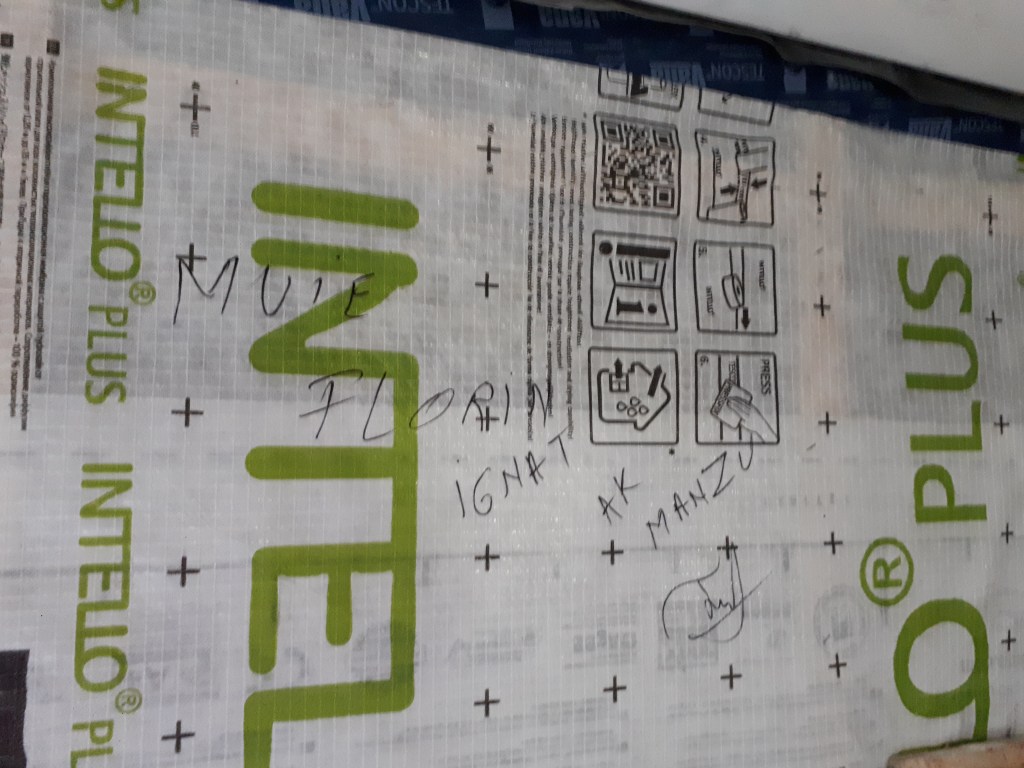

Inside the house I found the insulators had left their mark in a more pleasant way. After we placed plastic sheeting on the ceiling as a vapour membrane, the insulators were supposed to stick their wall membrane to it before adding the plaster board on top. Unfortunately they hadn’t realised that’s what we’d intended, and they put the plasterboard on without joining the two membranes together. To correct this I carefully unscrewed the board to stick down the membrane. What I found under one board was our insulator’s signatures, letting future generations know what they had contributed to the house. There is a long running tradition across the world of craftsman secretly or officially signing off their work. I taped the membranes together avoiding covering their writing, before hiding the signatures back behind the board.

While the floorboards upstairs are lovely, they are sadly too old to be easy to replace. Where the stairs were we needed to fill in the gap, but haven’t found any similar boards for sale. In the end we decided to go for more standard chipboard and put carpet down in the room that is planned to be our office. Chris did a great job filling the gaps, making the room much less of a health and safety hazard.

During the insulation installation the tap pipe in the old kitchen was bent, meaning the section needed to be replaced. Chris spent a bit of time planning out where the sink and toilet would go in this room before installing a new tap.

In order to avoid the dust being created by Chris’s work on the new doorway, I headed outside to plug some holes above the old steel in the back wall. At the moment this steel is rusting, as it hasn’t been properly protected from the weather. The rusting steel has the swollen, lifting up the stones above. As they lifted this has caused the various cracks in our back wall. In the long-term we need to decide what to do about this steel, but for now I spent some time scraping out the soft mortar and filling gaps, to help prevent water seeping into the wall, and causing further rusting.

Inside, Chris cut off the last few jagged edges from the doorway, before I stepped into repoint the loosened rocks.

But of course much of the weekend was spent continuing with digging the floor. While the previous weekend’s digging had been physically hard, this weekend’s had an added mental strain. In order to have space for all the material going on top we needed to dig down a minimum of 18cm, ideally 20cm. While this seemed to go fairly well on half the floor, the other half just refused to go any deeper. We measured it at 15cm, and then dug and dug through the tough ground, moving one wheelbarrow after another. Stopping to measure and….15cm. Sigh.

As well as our magically regenerating floor we came to realise that in one corner of the room our stonework stops at a level higher than the final floor level…..hm not ideal. We can’t have the floor level any higher as this will result in stepping down into the adjoining room. After some debate we decided we could create a concrete buttress around this portion of the wall, which would be hidden behind the kitchen cupboards. Hopefully the wall won’t fall down in the meantime…

With all these complications we have had a bit of good news. We’ve accepted an offer on our current house. After a few weeks advertising it ourselves, we’re very pleased and hoping things continue as planned. That does mean that we need to be able to move our mortgage across to the new house, which we can only do once it’s in a mortgagable state. Let’s just hope the floor stops regenerating and let’s us finish the job so we can get a kitchen in…

Idris supervising the work. -

Fanta-stic

As the days get longer we’re spending less time working in the dark and cold. For the first time this weekend I regretted putting on my full thermal set, always a milestone of the changing weather. The colour of the light also seems to have changed, becoming warmer, and less sharp.

Last weekend we rented the cut-saw in order to cut the stone to make a new doorway. As it was pretty much the same price to rent it for a weekend or a week, Chris opted for the longer option. This meant, once the door was done, he decided to trial cutting the concrete floor to see if it would speed up the process of removal. Having found the saw did the job remarkably well, he spend two evenings cutting out and removing the concrete, before the saw had to go back.

After Chris’s hard evening work we arrived on Saturday with a small amount of concrete left to remove and the then arduous task of digging the whole floor down around 20cm, ready for the insulation and concrete layer. First we had to take everything out of the room, squashing the bits and pieces in wherever we could. Rather than move them out and then back in again Chris and I finished putting up the batons Anna and I had started.

Once the room was clear we began to dig. Started on a tiny area in one corner I began to have serious doubts we’d get very far by hand. The ground was a mixture of grit and large stones, making it difficult to dig. There was another surprise in-store however, below the grit we found another concrete floor. This one was at least very thin and easily broken up with a pickaxe. Below that we hit clay, an even tougher material to scoop up.

Both days, spent breaking up the ground with a pickaxe, shovelling the lumpy, stoney mess into a wheelbarrow, and transporting it outside, were exhausting. We both spent a few moments at the end of each down, laid out flat on the bare clay floor, too tired to keep going. But after two days, the floor is nearly done. With the exception of a few doorways, and lots of refining to get the levels right, we’re there. With this nearly done we can soon get rid of the massive stack of insulation that is taking up half our lounge. Slowly the kitchen/ diner is transforming into a finished room.

On a side note our, much appreciated, insulation team, who previously seemed to survive solely on Red bull, seem to have changed over to Tango and Fanta, with cans scattered everywhere around the house. Perhaps their doctors told them they needed more fruit in their diet? It is the time of year for a health kick afterall? Still whatever is powering them on it’s great to see more and more plaster board up on the walls – hiding all our messy mistakes out of sight.

-

Opening doors

As spring begins to arrive, our garden has filled with snowdrops. It reminds me of the first time we saw the house. In fact, February marks a year since our first viewing. When I realised, I felt a slight sense of panic, thinking we’d already had a year of working on the house. But of course the sale wasn’t completed until May, so we still have time.

It was once again great to see the builders had been busy. All of upstairs is now plasterboarded, and most of downstairs has batons and insulation. The first corner had also been completed, satisfyingly rounded, as we’d requested.

My first job was to repoint the corner of the internal wall that sits over the new steel. Chris noticed a crack appear after we got the steel in place. It’s likely the wall shifted a little when we were doing the work. As the second steel will sit on this corner, it’s important to ensure it’s well supported.

Chris on the other hand got to play with our newly rented cut-off saw. This huge saw was needed to cut through the wall to create our new doorway from the kitchen/ diner to the lounge.

While the saw was well worth the cost to help get through the hard rocks, it created so much dust that Chris had to take regular breaks. Even upstairs I had to wear a mask.

The door came along fairly speedily, with us stopping at intervals to clear rocks from either side. Chris had to stop with his cutting halfway through to let me repoint, in order to stabilise the edge, which began to come lose.

Up in the attic, I set to work plugging up the holes around our two steels. A very simple job, that is aside from the gymnastics required to work in the confined space.

Having finished with the door, Chris began to use the cut-off saw to break into the concrete floor. Unfortunately for us, it appears the concrete was poured on top of another concrete floor. Still, the saw made quick work of the first layer. The first load is being added to our skip, now full and ready to go, but the layers below will be moved to our sinkhole, to try and refill this empty space and help create a soakaway for our rainwater.

It’s great to finally have our new doorway in place. I knew it would bring light into our slightly dark lounge, but it’s amazing what a difference it makes. The room feels instantly larger and more open. It also brings the two once seperate houses properly together.

This weekend, the work didn’t stop when we left the new house. Our old house needs some love and care. Having listed it last week, we have three viewings on Monday. To get the house ready we had a few bits of last minute DIY to take care of, plus general cleaning. If all goes well and one of the viewers decides to offer, then our deadline to get the house finished really will have solidified. Still, nothing like a deadline to get things moving.

-

A (mostly) Family Affair

There is certainly something magical about crisp, clean snow. Returning to the house this weekend we found a winter wonderland awaiting us, with sparkling ice crystals covering even the most mundane of objects, such as our suddenly very bling skip.

The magic had even infused the inside of the house, with friendly sprites having cracked on with insulating and boarding several rooms without us having to lift a finger. Bliss.

We were particularly relieved to observe the impressive curves the contractors have managed to leave in the walls, cutting the boards small to help contour the surfaces. Of course some places will be smoother than before but there’s still plenty of character remaining.

Amazingly, the contractors weren’t our only extra pairs of hands this weekend, with Chris’s friend Jay returning to lend a hand once more. Unfortunately for him he got paired with me, working out the giant jigsaw that was the ceiling, while Chris cracked on with the remaining electrics.

There was some reward for all this hard work, with there being no more perfect day for a lunch time dog walk.

Towards the end of the day the cavalry arrived, with my brother Luke and my sister Anna appearing to lend a hand. They got to work denailing the remaining woodpile, ready to be reused in and around the house. Though adding some work in the short -term, such thrifty recycling is saving us a small fortune in buying new wood.

On the Sunday, Luke and Anna were dragged back for more work, while Jay was let off for good behaviour. Having celebrated the dismantling of the scaffolding a few weeks before, Chris and Luke were forced to rebuild a tower in order to inspect the chimney. A slight damp wall below has made us aware that the lead around the chimney still has a slight leak.

Myself and Anna meanwhile cracked on with the ceiling. Somehow we came aground on several attempts, unable to find the rafters below with our screws. Nothing a bit of filler can’t fix though.

With the chimney inspected Luke and Chris went back to electrics, laying the complex lighting cables across the house.

Wanting a change of pace we then attempted to break up the concrete floor in the kitchen/diner. While we did make some progress with the pickaxe, Luke particularly having an impressive swing, it was decided a more heavy-duty machine might save some aching bones on another occasion.

Finally, myself and Anna began to put up the batons on the beams in the kitchen/diner, ready for the new ceiling to go in.

Phew – it’s amazing what a few volunteers and a couple of paid contractors can do to move a project along. With our next weekend assigned to sorting out our current house ready to go on the market, we should see even more magical transformations next time we return. It feels almost lazy. But I can live with that.

-

Tidying up

After our mammoth DIY holiday at Christmas, going back to weekends feels very slow. Still little by little things are coming along.

The main reason our structural engineer recommended we kept the brick wall in the center of the two upstairs bedroom, was because she thought the end roof purlin might be resting on it. While it hadn’t moved since the wall has come down Chris spent an evening installing a support to be on the safe side. As the steel didn’t have holes to attach wood to he made brackets to attach a plank of wood to the side of the structure below. This will allow us to attach a stud wall later.

Having started on one side of the doorway from the kitchen/diner to the lounge, and waited for the mortar to harden, Chris now installed the second lintel on the other side. Once this lintel has set we will be ready to cut out the doorway below.

We continued covering the ceiling with the old boards, though the missing floorboards in the middle of the floor meant we couldn’t get all the way to the top as we couldn’t position ladders far enough back.

Finally, we spent most of a day tidying up. This included brushing up mortar and plaster from the floor, sorting wood, adding more waste to the skip, and finding and sorting all our tools. We also moved all items away from external walls. This is all in preparation of our grant provided insulation team, who are returning next week to continue insulating, boarding and plastering our external walls. Exciting times!

Now the structural work is nearly done we are getting into more detailed considerations about the lay out. At home Chris rearranged our kitchen to demonstrate how wide the gap between our island and our kitchen units will be. I’m still mulling it over, as a narrow kitchen is the worst feature to have in a house. Might need to spend some time pretend cooking in our new space to decide.

-

It’s Christmas?

So far, in our renovation journey, we have only been able to take two weeks off, the rest being weekends and bank holidays. Those two weeks were both devoted to the roof. Now, with the new holiday year dawning, we were finally able to take another week off for inside work. That along with our Christmas holidays, meant we had nearly two full weeks to get on with some big jobs.

We started our time off with a job that had previously frustrated us; the insulation. Luckily the curse seemed to have been lifted, and we managed to get all the boards up on the various eaves in a day.

The only slight worry was Chris’s insistence that his ladder positioning, over a gap in the boards, was perfectly safe.

The large steel, that had been delivered a few weeks earlier, needed to be moved into the house in order to fit in the timbers that would slot into either side. We used fence posts to roll and swivel the heavy beam, as we weren’t able to lift it between us.

Our next big job was to remove the brick wall that divided the kitchen and dining areas. In order to do this, we had removed bricks and installed acro props and strongboys, to hold up the brick wall on the first floor, while we installed the steel to support it.

While Chris busied himself trimming down the large timbers to fit in the side of the steel, I began taking out the bricks below the acro props. I took the first brick out gingerly, worried more would instantly fall from above. Yet the wall remained strong. With each brick I removed I felt more and more confident the plan was going to work. Yet… as I made to remove the last brick I looked up to notice a bulge in the wall. The wall was faltering, unable to support itself.

Chris climbed into the attic and began passing down bricks, in an attempt to deconstruct the wall safely. However, with every brick he removed the wall became more unstable. Eventually we decided to tie a rope around one of the acro props and step outside the house, pulling it out from under the wall at a safe distance. A big crash and a cloud of dust followed.

Chris had been worried about the potential damage from the falling bricks, but luckily most had fallen through the gap where the stairs had been. Amazingly the whole disaster smashed one floorboards and put a few dents in our timbers, but not much more.

With the top part of the wall collapsed, we thought some of the lower wall, which had to be dismantled, might have come down too. But no such luck. We took apart the wall and piled the bricks outside, cleaning them ready for resale. Unfortunately, the fallen wall will now mean putting in a new stud wall on the first floor, however I was quite glad the brick wall fell when it did as it was clearly too unstable to not pose a risk during the rest of our works.

Raising the steel was without a doubt the most nerve-wracking part of our restoration works so far. It involved constructing a scaffold tower inside the house and setting up a pulley system. The pulley was designed for 180 kilos, with the steel being 160 plus the addition of the timbers. However, made of a thin white string, no thicker than a shoelace, it in not way looked up to the job. Not only this but the pulley wasn’t designed to hold the weight of the item once you had pulled it up, relying entirely on human input to stop the steel from crashing to the ground.

We were lucky to have several extra pairs of hands for the job, with Chris’s brother Rich, and my mum and dad, kindly coming to lend a bit of elbow-grease. Although the pulley did a great job, we simply couldn’t have lifted it without some brute force at the same time. We lifted it a bit at a time, building up the scaffolding underneath it for it to rest on.

The main difficulty was the length of the steel, being necessarily longer that the room was wide. We managed to get one end into the opening on one wall, but struggled to lift the other end into place, the steel becoming wedged against the wall. We had to deepen the hole and shave away at the stones on the walls. Eventually, after much heaving and hoing, the steel slotted into place, to everyone’s relief.

With the steel in place it was time to attach the beams. The beams on one side of the room had carefully been cut to the right size to butt up to the steel, and only needed brackets attaching to secure them in place. On the other side of the room we had the opening where there staircase once was. The other beams had been cut to allow the steel through. We therefore needed to remove and replace all the beams.

With all this done we had a somewhat more open plan space than originally intended, but still a big step forward and the last big structural job completed.

During one of the days where I had been working on something inside on my own, Chris began digging around in the garden to try and work out the drainage. There was a strange area within the garden, close to a telegraph pole, where the ground seemed to bounce beneath our feet. Having spent a bit of time digging in this spot, while looking for the outflow of our drainage, Chris was amazed to see a hole open up beneath him. Sticking a rod down to assess the depth, he found it went down some 2m. The bouncing ground was where the tree roots were suspended over empty space.

As the hole was so close to the telegraph pole we called Scottish power to assess the situation. They agreed they would need to move the cable supporting the pole. Having dug a hole to see if the ground would be suitable, they found the hole went further than expected. Eventually, they managed to find a suitable spot, and we now know of a massive hole at the bottom of our garden. It is likely to have been caused by our broken drainage, washing away the soil beneath our trees. Due to the lack of soil the Scottish power team decided an ash tree next to the power line was too unstable to leave standing. As our plan is eventually to lay the hedge beside the road, we requested the ash tree be coppiced so we could lay any new growth into the hedge.

While a big hole in your garden is by no means ideal, we’re hoping we might be able to repurpose it into a soakaway. Currently it seems that any drainage from our house most likely ends up on the road. However, with no road drainage close this isn’t ideal in winter, potentially creating icy patches. A soakaway might be the best solution. First, however, we need to get through to the local council, as some of the sink hole appears to have encroached on the edge of the road…

With the steel work completed we moved on to another new structure of the kitchen/diner; a new doorway connecting the lounge and dining room. With the thick wall between, what was once two houses, it won’t be an easy task, involving the installation on three lintels. For now the mortar needs to set around the first lintel, before we can risk removing more stones.

On our final day we started a completely new task, for good measure, starting to replace the wooden ceiling slats. To do this we needed to first cover the insulation with a vapour membrane. This was an awkward job, involving at least three pairs of hands, luckily Chris’s friend Jay (and his dog Rosie) joined us, making an impossible task much easier. Once the joins in the insulation were sealed with aluminium tape, and the vapour membrane semi-attached, we began to attach the old ceiling boards. Having spent time marking where the rafters were onto the insulation boards, we then realised we couldn’t see the markings with the black plastic in the way. A little guesswork was therefore required to place the screws. I was quite pleased with the finished result. There’s definitely lots of filling and sanding on the horizon, but considering how old and brittle they are they went back up really nicely. With one room done, and two ready for boards to go up, it was a good end to our time off.

Our final bit of good fortune on our time off was to sell the majority of our scaffolding, keeping just one bay for ourselves. Having sold it for the same price we brought it for, we saved all the costs of renting scaffolding over the many months it stood around the house. Our old stairs also went to a new home, though we offered these for free. These are going to replace a broken set in a house currently being renovated.

So that’s it for a while, back to evenings and weekends. I would prefer to be able to give up work and just do the renovation project full time, but unfortunately no one has offered to pay me to renovate my own house. No idea why not.

-

Stepping down

After a disappointing and frustrating day together, both myself and Chris headed back separately to do a little more work. Chris had to take a day off work for the delivery of the steel, while I took a separate day off as I had holiday to use up before the end of the year.

Chris’s day at the house was amazingly productive. As well as a bit of tidying he managed to get the stairs prepped for removal by taking away all the supporting wood. He also took out the rest of the doorway I had started to disassemble. He considered removing the stairs alone, but realised that it would be easier with two people. And, of course, he’d never hear the end of it if I wasn’t there to see the stairs finally come down.

Downstairs he then prepped the wall for demolition, taking out one doorway and inserting the acro props where required.

My day alone was more fiddly, and less physical. All the boards we’d removed from the ceiling needed prepping to go back up. This meant removing all nails and any loose bits of wood.

There are very few walls left with plaster on them, but Chris pointed out the otherw day that any internal walls would need stripping up to a meter from the edge, as the external insulation will be added to the first section of internal wall to reduce heat loss.

A final small job was removing the other doorway from the wall that was going to come down.

Having accomplished so much separately we were in a good place when we returned to the house on Christmas Eve. Our first job was to remove the old stairs. Despite Chris’s insistence they would just slide out, we did have to cut through a fair bit of wood to get them loose. As with all wooden structures in our new house, the previous workmen/women had insisted on sticking six inch nails through everything they could. Alarmingly we could see the brickwall above wobble as we tried to loosen the stairs from their nails, meaning we resorted to cutting them out, for fear of toppling the wall we were trying to save.

Our final job was to install two pad stones, for the big steel to sit on. While the pad stones in the attic had been fairly straight forward, building them into the thick walls downstairs was time-consuming, particularly as it involved breaking up very large stones to open up holes in the right places. Still, with the pad stones in and the concrete around them given a few days to set, we should be ready to take down the wall and install the steel next time we come to the house. It all sounds so simple when you put it like that….

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.