I spent a day finishing off the plastering on the kitchen wall, starting with the remaining areas surrounding the bare stone wall. I would have like to leave more of the stone bare but the position of the wiring meant it wasn’t possible. Still I think what’s remaining will look nice.

Once the lime plastering was finished I did the plasterboard next. It was nice to get these awkward remaining sections done.

We’d spent an evening emptying out the kitchen and cramming everything into the utility room and lounge. With the room empty and plastering done I went round the room scrapping old plaster off the floor from previous work and then swept and hoovered to get the floor ready for grinding.

The floor grinder appeared, as did a set of plastic zip doors that we stuck across the two entrances to at least minimise the dust in the rest of the house.

As I had two days off work this week the plan was for me to do the grinding while Chris was at work, however it turned out the machine was pretty hard even for Chris to control, while I simple didn’t have the upper body strength to wrestle with it. So instead, we decided on an evening session to get the first grind done, with Chris on the grinder and me sweeping up.

The dust created by the machine was incredible – filling the room and building up in thick piles. We’d invested in some better masks, which saved our lungs from the worst of it.

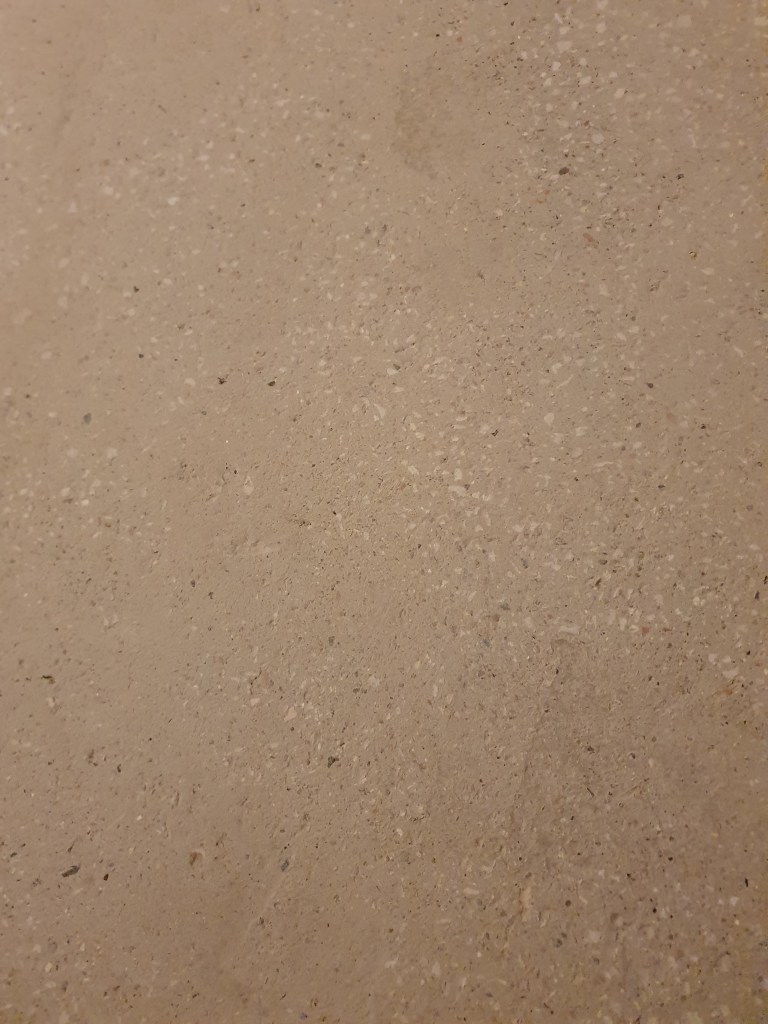

The grinding and polishing stages consist of 7 different grinding and polishing disks, each getting finer. The first stage consisted of small pads with large metal rectangles that scour the unevenness off the surface, flattening it out. We’d expected the machine to rest of its wheels, with the pads just touching the floor between, but actually the whole weight of the machine rested on the rotating pads, which was why it was so hard to control.

Chris made three passes of the whole room before we swept up and hoovered.

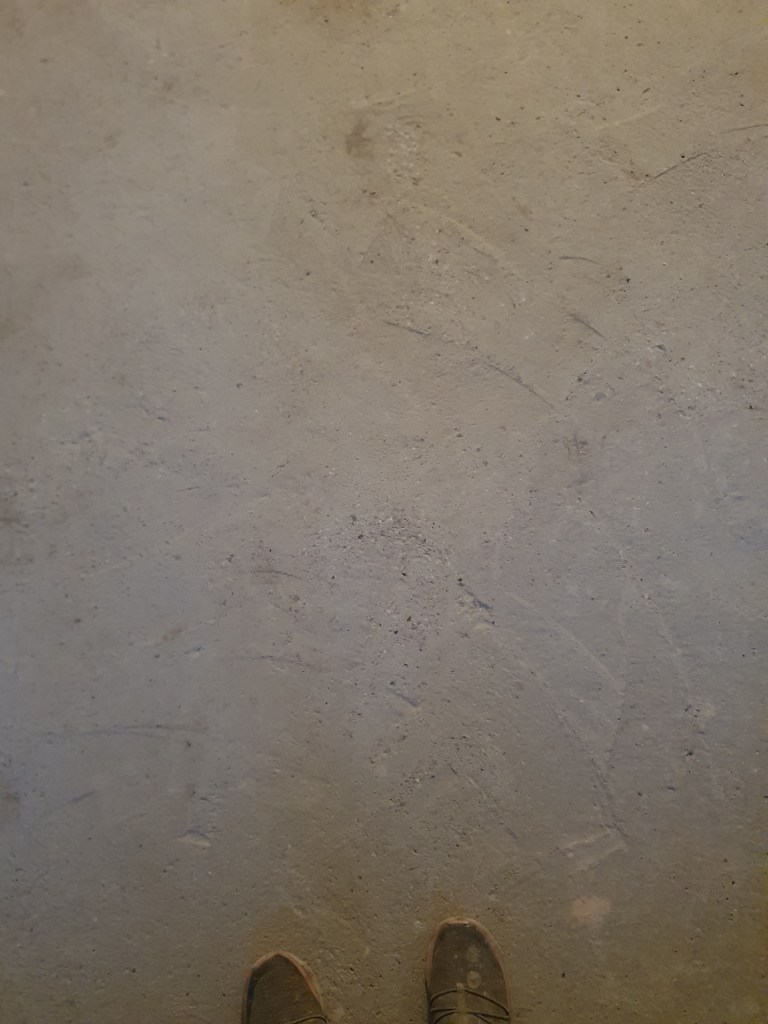

We hadn’t been sure how much of a difference we’d see in this first stage, but it was very noticeable, with the surface flatter and smoother, and more of the aggregate visible.

The next day I got to work with the hand grinder, tackling the edges where the large machine couldn’t reach. I’d thought the large grinder filled the room with dust but somehow the hand grinder created complete white out in a few minutes. I had to open the windows and pause to let the dust clear every five minutes as I couldn’t see what I was doing.

With the edges done and the room swept and hoovered again, the plan was then to spread a thin layer of concrete across the surface to fill any gaps. We would then grind off the excess. However, when I started spreading the concrete mixture on the floor I found the mixture immediately solidified when it hit the floor, and it was impossible to spread. Calling Chris at work I explained the issue and he said he would have a look when I got home. Giving it a try himself and finding exactly the same issue, and then looking up reviews online and finding other people also had the same problem, he decided simple to spot treat the worst holes, and give up on a complete covering.

Now we’re off for our Christmas break, so nothing will be done for a week. But then we’ll be back to get the second grind done. I’m hoping once we get to the polishing stages the machine might run a little smoother, and I might be able to control it, meaning Chris doesn’t have to do all the work with the big machine.

To end on a less dusty note I was looking for a boring green lampshade for our bedroom on ebay and came across a broken tiffany lampshade. I put on the lowest bid and won it. My mum does stainglass so hopefully she can show me how to fix it. I’m not sure how to attach it to a light, still it’s very nice and I thought it was worth a go. And afterall , daffodils and a Welsh country house are very well suited to one another.

A Merry Christmas everyone, or Nadolig llawen in Welsh, and a Happy New Year, a Blwyddyn Newydd Dda!

Leave a comment